Keene Additive Manufacturing Makes Leaps in Customized Design Innovation with Raise3D Technology

Chris Dubriske first got into 3D printing as a way to quickly and cost-effectively produce custom end caps for a consumer product at his lighting company. After learning the ins-and-outs of 3D modeling and printing, his team started printing other parts for local companies. Recognizing a need for customized design innovation that was only possible through 3D printing, Keene Additive Manufacturing was born.

Keene Additive Manufacturing was born from the recognition of the customized design innovation was only possible through 3D printing.

Dubriske was able to use Raise3D printers to improve the manufacturing process for his father’s flotation product.

These days, Keene Additive Manufacturing does contract work for machine shops in the local area, including prototyping and design work. One of the many things they’ve been working on lately is designing and producing proprietary products for the fishing industry. Dubriske was able to use Raise3D printers to improve the manufacturing process for his father’s flotation product, which used to come in multiple parts, including a section carved from foam. He notes that it was a difficult and messy process to cut the foam and cover it in epoxy, but by using 3D printing, they can manufacture the entire product in one piece. Dubriske notes, “It really changed the aesthetic of this product while keeping the same functionality, and made the manufacturing process much easier.”

How 3D Printing is Changing the Game for Keene

With years of experience in lighting design and manufacturing, Dubriske is familiar with traditional manufacturing processes and recognizes the many benefits of additive manufacturing as opposed to traditional methods. For instance, the rapid turnaround time: “One of the huge benefits of 3D printing is how quickly you can get the part into your hand. This end cap is a good example; it’s something that didn’t exist, but we had a need for it. A few hours of design time, a few hours of printing and you have a part in your hands.”

You have a part in your hands with a few hours of design time and a few hours of printing.

3D printed designs can be changed easily whenever the need arises.

Dubriske also appreciates that 3D printed designs can be changed easily whenever the need arises, without any significant cost or wait time. Unlike traditional manufacturing where manufacturers might be locked into a certain mold or locked into a certain design because they made a bulk order, it’s simple for clients to change their design either for aesthetic purposes or functional purposes.

Choosing Raise3D for Reliability, IDEX, and Large Build Volume

Dubriske chose Raise3D printers over other options for several reasons, including reliability, technical support, IDEX capability, and the affordable price point. A significant draw was the IDEX dual extruders of the Raise3D E2, the first printer used at Keene. He notes that when printing small parts, you can print two parts with the IDEX Duplication mode, essentially getting two printers for the price of one.

Raise3D E2 can print two parts with the IDEX Duplication mode.

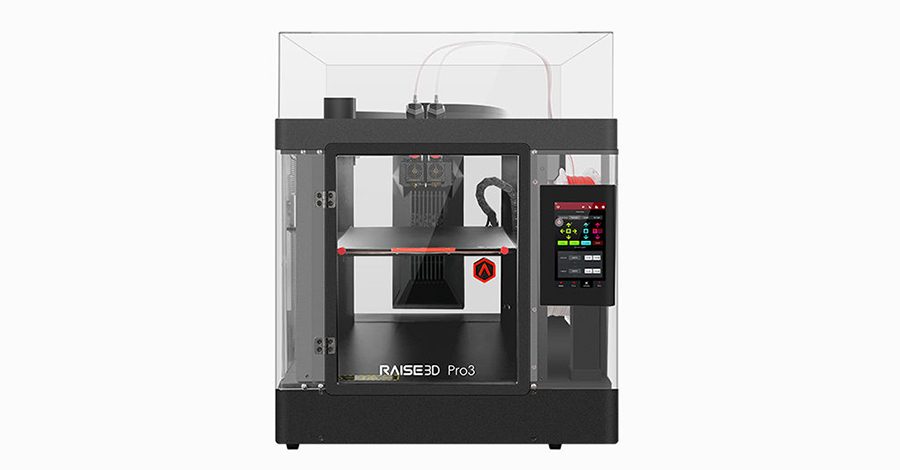

Raise3D Pro3 printer with a larger build volume and greater Z-capacity.

After Keene began expanding, Dubriske wanted to purchase a printer with a larger build volume and greater Z-capacity. He landed on the Raise3D Pro3. The team at Keene Additive Manufacturing has been able to depend on the Pro3’s impressive reliability: “It takes maybe one or two test prints to get a Gcode and get all the settings perfectly, and then we account for almost no failures. We’ve had zero issues with the Pro3s—you just take the part off, hit go, it runs another one; it’s really been awesome.”

Doubling Capacity with Hyper FFF® Hyper Speed Printing

Upgrading their Pro3 printers to Hyper FFF® has allowed Keene to greatly increase their production capacity. “It’s really increased our throughput by more than double,” says Dubriske. What was once a 30-hour part may now be a 14- or even 12-hour part to print.

Recently, Keene had a request for a rush job for a tall print. What would have been a 50-hour print was reduced to just 16 hours with the Pro3 with Hyper FFF®, and Keene was able to ship the print out the very next day. Dubriske says that without the Hyper FFF® upgrade, it’s unlikely that they would have been able to take on the job.

Raise3D Hyper FFF® allowed Keene to greatly increase their production capacity.

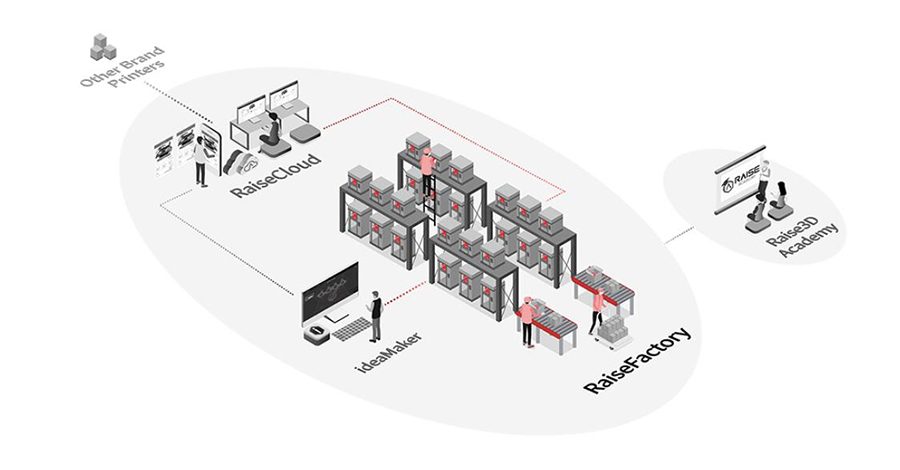

Raise3D Ecosystem

Saving Time and Effort with the Raise3D Ecosystem

Dubriske notes that another great benefit of using Raise3D is the integration between ideaMaker, RaiseCloud, and Raise3D printers—all of which were designed to work together seamlessly. “Having ideaMaker profiles already set for all the Raise3D machines to all the different materials is really a huge time-saver. You’re beginning from such a good starting point that the failures are few and far between.” He adds that because of the integration, there’s a “high degree of confidence that the part is going to come out really clean.”

“The integration of ideaMaker and RaiseCloud with all the machines makes everything very efficient,” says Dubriske. “You can run it all wirelessly, it tracks all your print jobs, you can really see if there are any issues with any machines. So all of those things have been a huge benefit for us and I’m very happy working with Raise3D printers.”

The Next Steps for Keene Additive Manufacturing

As Keene continues to grow, they’re looking to invest in new printers—among them, the Raise3D E2CF. Dubriske recently submitted a request form to Raise3D’s Sample Parts Program to see if the printer and its compatible materials are right for them. They received a glass-filled nylon sample part printed with the E2CF: “A very impressive part, we received it really quickly, maybe a week after we submitted the form we had the part in our hands,” Dubriske says. He appreciates that the part comes with the support material so that he was able kind of get a feel for the material, what it looks like, and how well it fits to the part. “The quality is outstanding.”

The Raise3D Sample Parts Program showcases the quality of multiple Raise3D printers and filaments. Anyone in the US can request a sample part: Just use the sample selector to filter parts based on your target industry, application, material type, and printer model.

“Overall, we’ve been very happy with our Raise3D printers,” says Dubriske. Keene Additive Manufacturing has expanded from just one E2 to eight printers and the team utilizes the entire Raise3D ecosystem. Dubriske says that Customer Support has been very quick to respond and help solve issues, getting new parts out as quickly as possible. He adds, “We’re looking forward to more printers coming out in the future!”

The reliability, speed, support, and seamless ecosystem offered by Raise3D have allowed Dubriske to create an entirely new additive manufacturing business in addition to his lighting company, and make leaps in customized design innovation that now help manufacturers in the local area. Keene’s rapid expansion over the last two years shows that 3D printing is on the rise as a faster, more flexible, more cost-effective alternative to traditional production methods. With Raise3D’s focus on user-friendliness and dedicated customer support, anyone can join the next generation of manufacturing, whether it be for rapid prototyping, jigs and fixtures, or end-use parts.

This case study was published on November 30, 2023 on https://www.raise3d.eu

The reliability, speed, support, and seamless ecosystem offered by Raise3D.