3D printing with skin compatibility

3D printing has revolutionized the manufacturing industry, making it possible to produce a wide range of products quickly and cost-effectively. However, this technology has also opened up a new horizon in terms of the skin compatibility of filaments. The biosafety of 3D printing materials has become an important consideration, especially in areas where skin contact is unavoidable.

Why is biosafety important?

The skin is the largest organ of the human body and serves as a barrier between our inner self and the outside world. It is sensitive and can react sensitively to certain substances. For this reason, it is crucial that materials that come into direct contact with the skin are biologically safe. A lack of focus on biosafety can lead to skin irritation, allergic reactions and, in severe cases, health problems.

The DIN EN ISO 10993-5 certification

DIN EN ISO 10993-5 is an internationally recognized standard that evaluates the biological safety of products intended for the human body, including the skin. This certification ensures that materials are specifically tested for their compatibility with the skin. A 3D printing filament that receives this certification has been proven to be safe for skin contact.

Applications in medicine

The link between 3D printing and biosafety opens up exciting application possibilities, particularly in medicine. Prostheses, orthoses and other medical devices can now be made to measure and at the same time compatible with the skin. This significantly improves patients’ comfort and quality of life.

P-Filament 721 and P-Filament carbon 411 from PPprint: Now also biologically safe for skin contact

The world of 3D printing is constantly evolving, and in this context, Hohenstein Laboratories GmbH & Co. KG recently made an exciting announcement. They have successfully certified all color variants of their “P-Filament 721” as well as their “P-Filament carbon 411” according to DIN EN ISO 10993-5. This certification is a significant step that opens the door to a variety of new applications in healthcare and beyond.

“P-Filament 721”: An all-rounder for medical technology

The “P-Filament 721” was already known for its impressive chemical and mechanical properties, which made it a popular choice for medical technology applications. It was often used for the production of orthoses and prostheses. But now, with the new certification, it becomes even more versatile. Not only can this 3D printing material produce medical devices and aids, but they can also be worn directly on the skin without hesitation.

“P-Filament carbon 411”: Powerful and safe

In addition to the “P-Filament 721”, the “P-Filament carbon 411” has also received this prestigious certification. This carbon fiber filament is characterized by its exceptional strength and lightness, making it ideal for a wide range of applications. Now that it is classified as biologically safe, it can also be used in skin contact applications such as the manufacture of body-worn devices.

Advantages of P-filament carbon 411:

- Optimized for low warping

- Simple and reliable printability

- No pre-drying required

- works with easily removable P-Support 279 filament

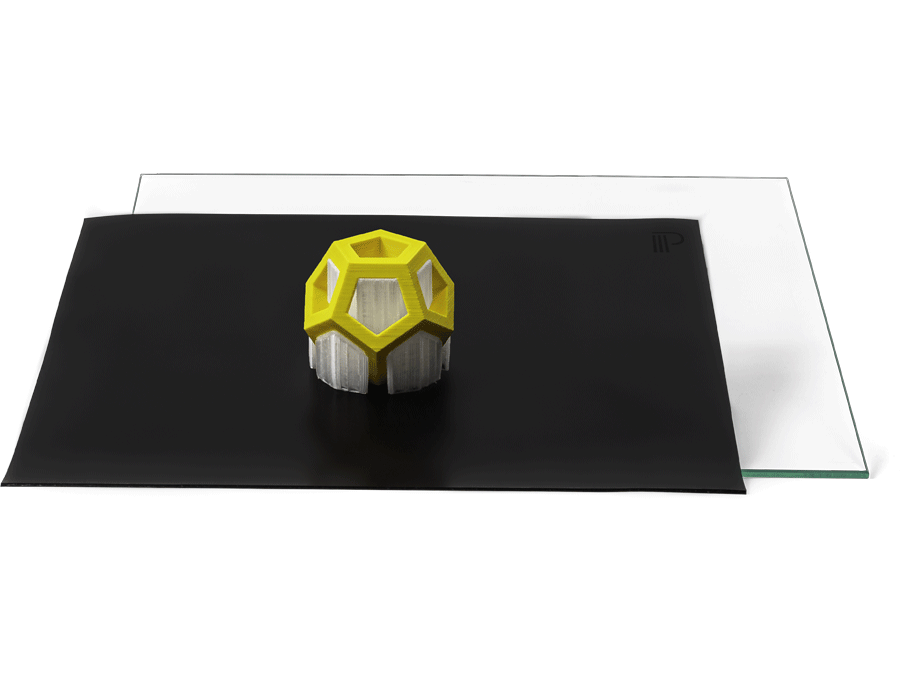

Printing polypropylene made easy with P-Surface 141

Printing polypropylene can be a challenge as it usually only sticks to itself. Fortunately, PPprint offers a solution: the P-Surface 141. This innovative addition to printing beds has been specially developed to enable trouble-free printing of polypropylene. P-Surface 141 ensures uniform adhesion throughout the printing process, prevents delamination and deformation and facilitates high-quality polypropylene prints. This simple and effective solution makes polypropylene prints more versatile and is an indispensable tool for 3D printing enthusiasts and professionals.

A big step for the 3D printing industry

The certification of “P-Filament 721” and “P-Filament carbon 411” is an important milestone for the 3D printing industry. It opens the door to the development and manufacture of high-quality, customized medical products that can be worn directly on the skin. This is particularly important in orthopaedics, prosthetics and many other medical fields.

Beyond medicine

In addition to medical applications, the biological safety of filaments is also important in other industries. In the cosmetics industry, 3D-printed applicators and skincare products can be individually tailored to the needs of the skin. In the fashion industry, customized garments can be produced that are not only stylish but also skin-friendly.

The future of 3D printing looks brighter than ever, and we can look forward to seeing where these innovations in medical technology will take us.