Pianca’s Innovative Journey with 3D Printing Furniture Parts and Prototypes

Located in Gaiarine, Italy, Pianca is an Italian company functioning in the furniture sector, and focuses on crafting systems and furnishings for residential spaces, tailored to the evolving lifestyle marked by flexibility and mobility.

“Our approach to design is oriented towards the customisation of products and environments, in order to meet the needs of a lifestyle marked by flexibility, mobility and change, but with the desire to “feel as comfortable as at home”,” as Pianca themselves state.

Pianca is an Italian company functioning in the furniture sector

Pianca faced challenges with traditional prototype commissioning from external craftsmen

Challenges in an Industry Rooted in Tradition

Pianca faced challenges with traditional prototype commissioning from external craftsmen, using subtractive production techniques. Long lead times, high costs, and a lack of control over production were constant issues, making the process slower. Pianca recognized the limitations and inefficiencies associated with outsourcing.

3D Printing as a Solution

Pianca looked for an alternative, and found that 3D printing was an innovation that had the potential to internalize the prototyping and testing phase. Compared to conventional subtractive methods, 3D printing offered control and flexibility. Pianca embraced this technology, as it also fomented sustainability in products and processes.

Pianca found Raise3D to be the perfect fit for their requirements. With the best price/performance ratio, reliability, and performance, Raise3D offered printers capable of handling medium and large-scale projects simultaneously, thanks to the build volume.

Pianca predominantly uses PLA for its 3D printing, a good choice for lower resolution prints needed for prototyping. The team employs 3D printing for 1:1 scale models to study the interaction between different components of the same piece of furniture, as well as for small batch production.

Pianca found that 3D printing was an innovation that had the potential to internalize the prototyping and testing phase

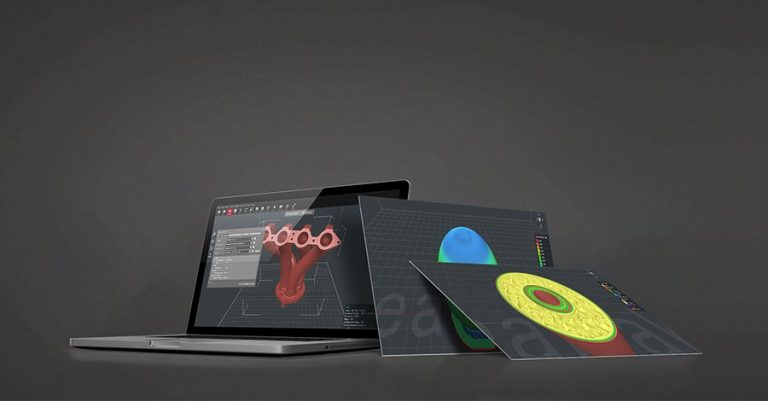

ideaMaker is an intuitive piece of software and helped streamline Pianca’s 3D printing workflow.

ideaMaker

Raise3D’s unique 3D slicer software – ideaMaker is also a welcome addition. Matteo Giacomini, from Pianca’s R&D department, emphasizes the reliability of the preview functionality, ensuring that the team can confidently anticipate the final results. This not only aids in cutting parts into smaller components but also facilitates the repair of damaged files. It’s an intuitive piece of software and helped streamline Pianca’s 3D printing workflow.

Conclusion

Pianca’s journey with 3D printing, marked by a commitment to innovation and sustainability, showcases the transformative power of technology in the traditional realm of woodworking and furniture design.

Internalizing the prototyping phase through 3D printing has proven to be a game-changer for Pianca. The ability to oversee the entire supply chain, ensuring seamless interaction between parts, has translated into significant time and cost savings. The team’s focus on prototyping, supported by precise previews and reliable software, underscores the efficiency gained through embracing 3D printing technology.

Internalizing the prototyping phase through 3D printing has proven to be a game-changer for Pianca

This case study was shared by Ciano Shapes, a Raise3D reseller based in Italy, and was published on https://www.raise3d.eu on January 12, 2024. (English)