Raise3D unveils groundbreaking DF2 solution at Formnext

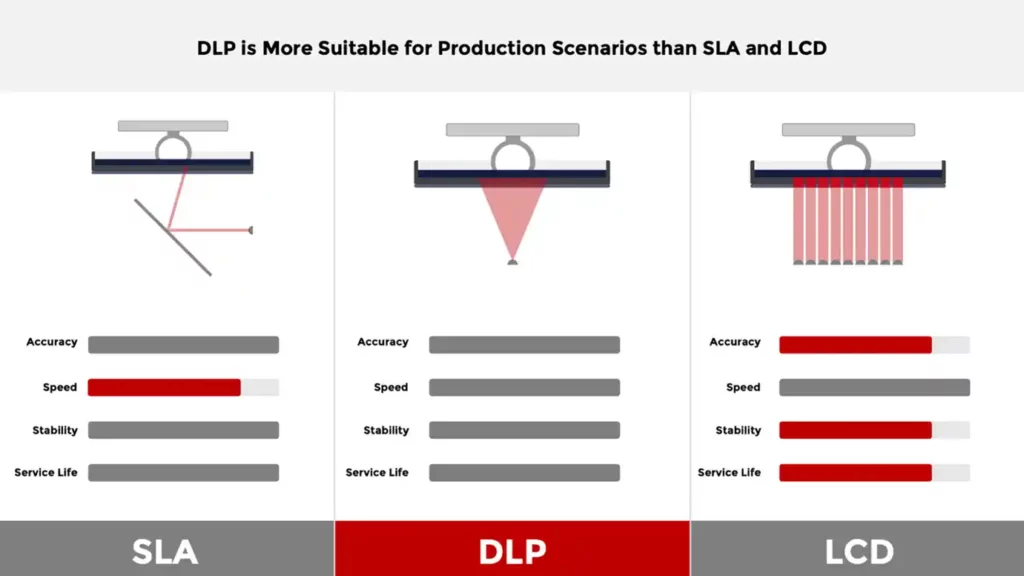

Raise3D, a renowned provider of flexible manufacturing solutions, launched the innovative DF2 solution at Formnext in Rotterdam on November 7, 2023. This step represents a significant milestone for the company, as it is the first time Raise3D has entered the photopolymer resin 3D printing market. The DF2 solution, based on advanced Digital Light Printing (DLP) technology, promises fast printing speeds, refined surfaces, high precision and exceptional reliability.

The DF2 solution has been developed specifically for engineering prototyping, the production of manufacturing aids and small batch production. It offers a wide range of high-quality resins and features a traceable workflow that reduces working time and optimizes the use of resin in the 3D printing process.

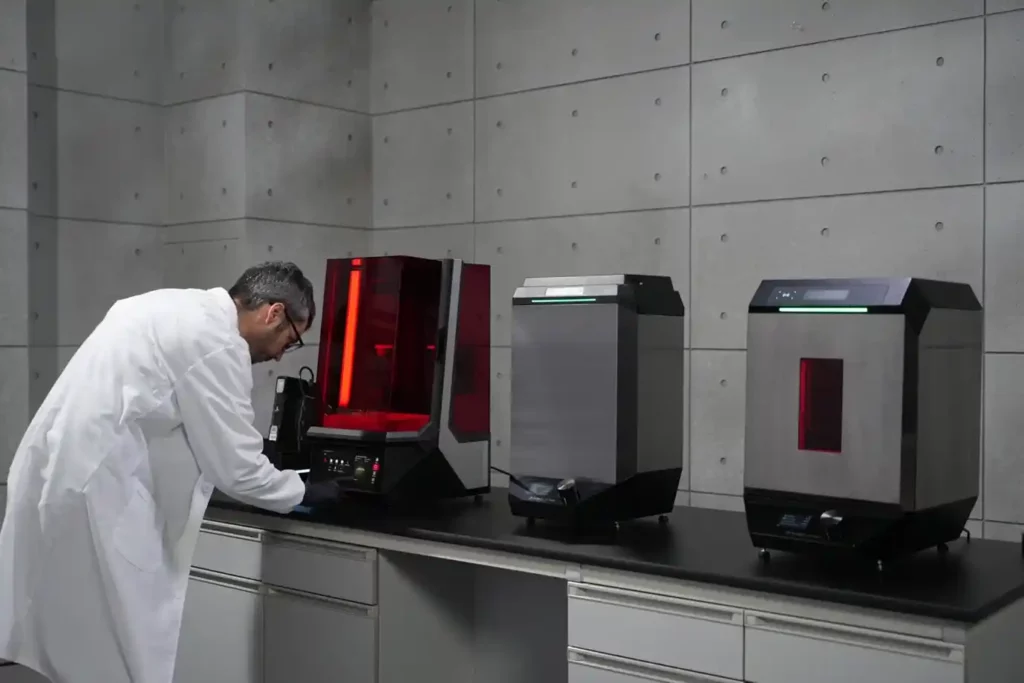

The DF2 solution comprises several components that enable a complete 3D printing workflow:

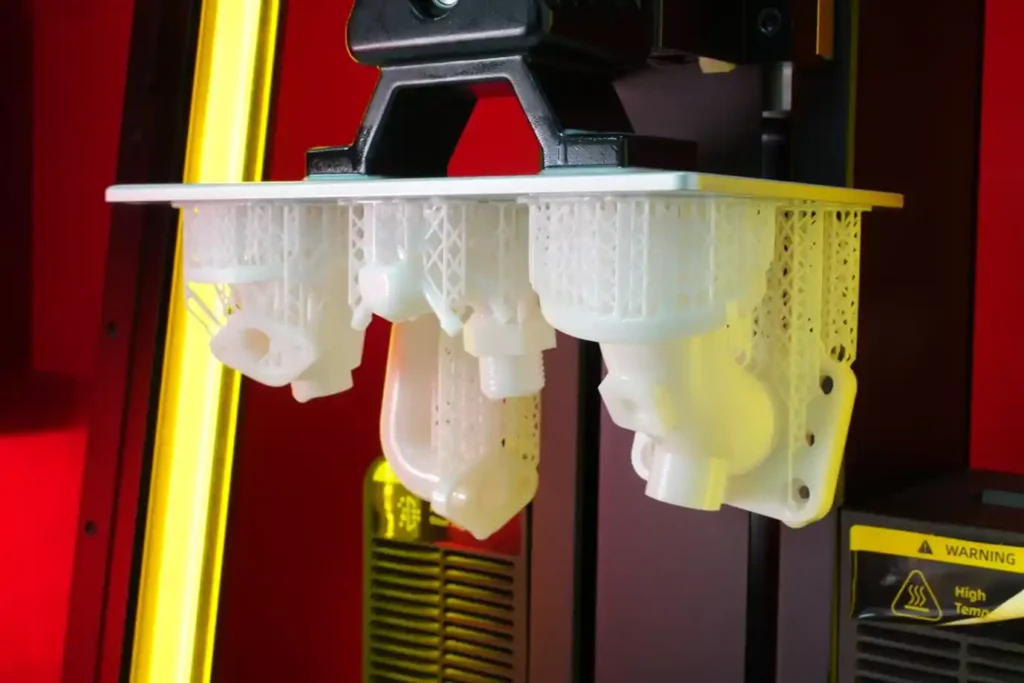

- Raise3D DF2 3D printer:

This DLP printer produces high-resolution, smooth and repeatable parts in low volumes. It features a precise and reliable Z-axis lifting system, efficient material management, a heated chamber, a high-quality optical system and advanced anti-aliasing and air-peel technologies for quick and easy layer removal. - Raise3D DF Wash:

An automated cleaning solution that provides efficient process control and easy maintenance. It features powerful cleaning capabilities through twin turbine wash and hand wash simulation, as well as a dual fan air drying system. - Raise3D DF Cure:

An advanced curing station with multiple UV curing and heating profiles that utilizes dual curing sources across multiple wavelengths (365/385/405 nm). - Raise3D resins:

A selection of resins tailored for different applications, with more options to be released soon.

This first introduction to the DF2 solution shows how Raise3D is pushing the boundaries of 3D printing by offering a solution that sets new standards not only in the quality of prints, but also in the efficiency of the entire printing process.

Strategy and partnerships in the resin materials sector

Raise3D continues its innovation journey and continues to invest in the development of resin materials to advance the field of 3D printing. The company has set itself the task of establishing resin development as a core competence and reallocating internal resources to further develop this area. With the launch of the DF2 solution, Raise3D has already validated a wide range of materials, including products from well-known partners such as Henkel and BASF Forward AM.

The DF2 solution supports an open materials platform that encourages innovation and empowers customers to explore new possibilities in resin 3D printing. With the launch of the DF2 solution, Raise3D also announces the ORP (Open Resin Program). This program is a collaboration between Raise3D and resin manufacturers to identify and select high-performance resins for the DF2 solution.

Advantages and features of the DF2 solution

Raise3D highlights several advantages and features of the DF2 solution that set it apart from other solutions:

- Traceable and easy to use: with Smart Build Plate technology, which uses RFID tags to record the type of resin used and the wash and cure settings, operators can manage the post-processing stages effortlessly.

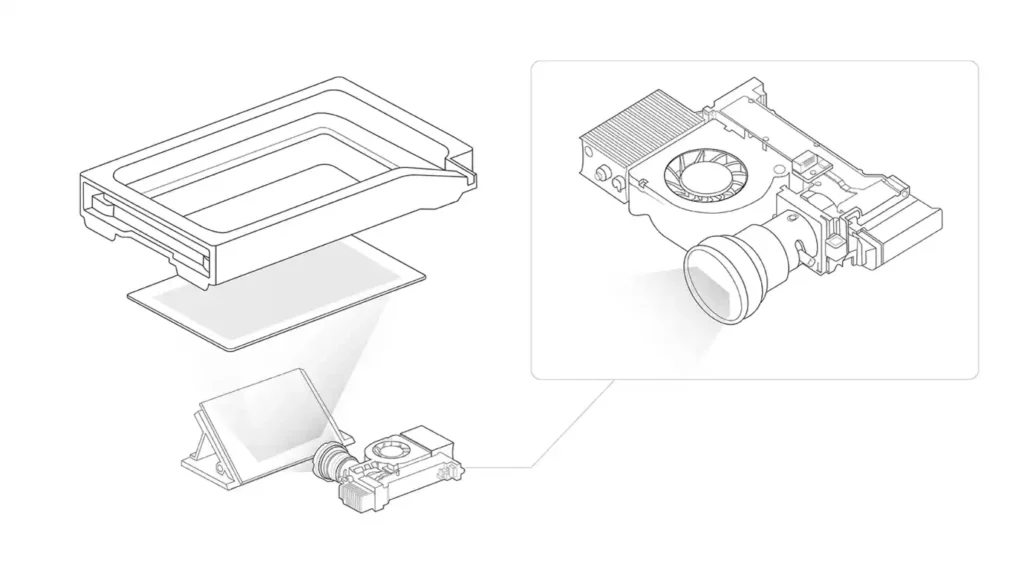

- Superior print quality: The DF2 solution achieves detailed and smooth prints thanks to optimized optical components, high XY pixel resolution and the integration of anti-aliasing technology.

- Increased reliability: With a state-of-the-art light engine, precise optical control and a stable printing environment, the DF2 solution ensures long-lasting use and excellent image clarity.

- Efficient and safe workflow: The DF2 solution reduces manual tasks with automated dewatering and door mechanisms and enables effortless maintenance.

These aspects of the DF2 solution show that Raise3D not only introduces innovative technologies to the 3D printing market, but also improves the user experience by simplifying the workflow and increasing reliability.

Pricing and global launch

The DF2 solution is competitively priced to make it easy to get started with advanced 3D printing technology. With a pre-sale launch on November 7, 2023, Raise3D is offering an exclusive 10% discount on all orders placed between November 7 and November 30, 2023. Delivery to customers is planned for the first quarter of 2024. The pricing structure is as follows:

Customers who opt for the complete package can benefit from significant savings. It should be noted that the prices quoted are for the EU and US markets and may vary in other regions.

Delivery of DF2 is expected in Q1’24 and will be on a first-come, first-served basis.

Questions and answers

Raise3D has developed the DF2 solution to extend the company’s FFF technology and meet the different needs of users in various application scenarios. With a focus on engineering applications, the DF2 solution offers high precision, smooth surfaces, reliable performance and an optimized printing process. In addition, Raise3D has identified several production applications where the combined use of FFF and DLP 3D printing is ideal. The DF2 solution enables users to perform prototype verification in various application fields and facilitate low-volume production of detailed and consistent components.

Edward Feng, CEO of Raise3D, emphasizes the company’s goal of making resin printing hassle-free for production, with unmatched repeatability, quality and speed. The DF2 solution is a solid step in this direction.

The decision to use DLP technology is based on Raise3D’s commitment to providing its customers with the best balance of accuracy, speed, stability and longevity of the light source. After careful evaluation, the company found DLP technology to be the best fit for production scenarios, as DLP projectors maintain a consistent pixel count regardless of print size and offer numerous advantages over LCD and SLA technologies.

About Raise3D

Raise3D designs and manufactures high-performance 3D printers and additive manufacturing solutions for SMEs and large enterprises. With offices in California, Texas, Rotterdam and Shanghai, Raise3D is an ISO9001:2015 and ISO14001 certified company and is positioned as a leading developer of complete solutions using FFF additive manufacturing technology for polymers, composites and metal materials.